Merging process steps offers advantages

A customer from the industrial products sector has previously used individual processes for the assembly of cooling systems. This resulted in several disadvantages, which we eliminated by planning an overall process. An investment of €45,000 was made for the implementation.

Our approach

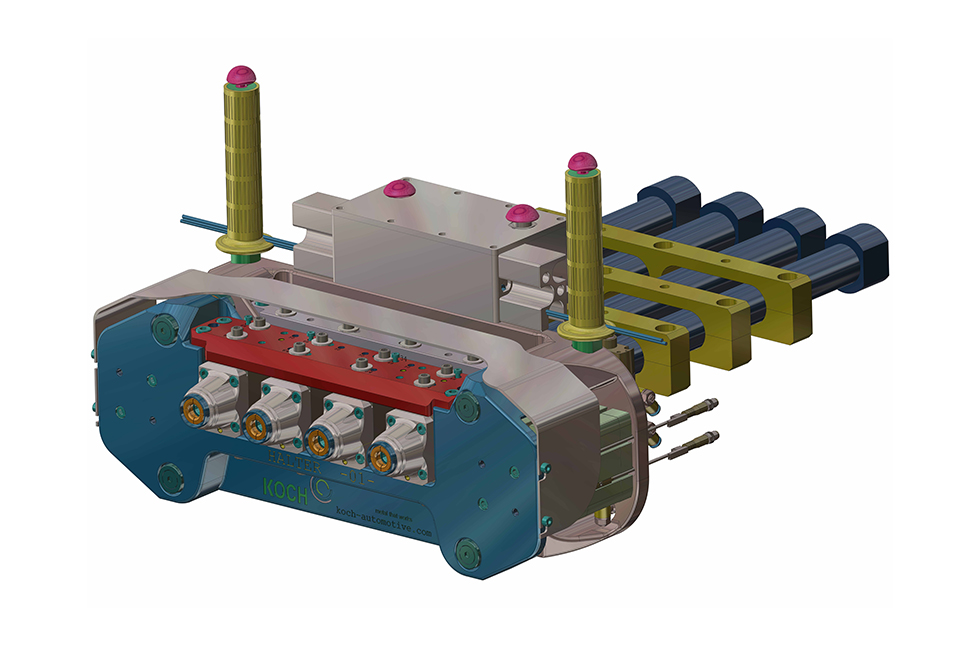

In order to efficiently combine the individual isolated process steps, we had to develop and manufacture a semi-automated worker solution. The handling system used for this is fully automated and can be used for several variants, as it is modularly interchangeable. The drives are operated hydraulically via interfaces that our customer uses. To enable safety and process monitoring, the control system in this case was based on a mini PLC solution.

Technologies used

The challenge of bundling the individual assembly processes was extremely complex, so we had to use state-of-the-art technologies. When designing the product in particular, it was necessary to simulate the implementation precisely beforehand using CAD software in order to prevent any sources of error from occurring in the first place. The product was then manufactured mechanically on a contract basis.

Advantages for our customers

Merging the process steps brought a number of advantages for our customer. By reducing set-up and process costs, two cost drivers were cut at the same time. In addition, the risk of accidents for employees was reduced and data collection of process-relevant KPIs was implemented.