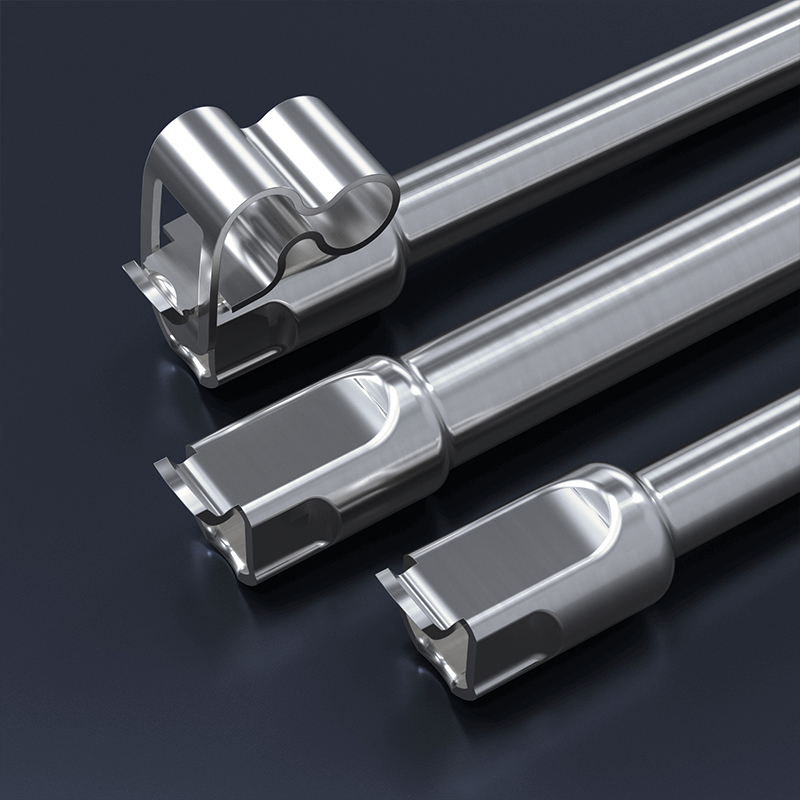

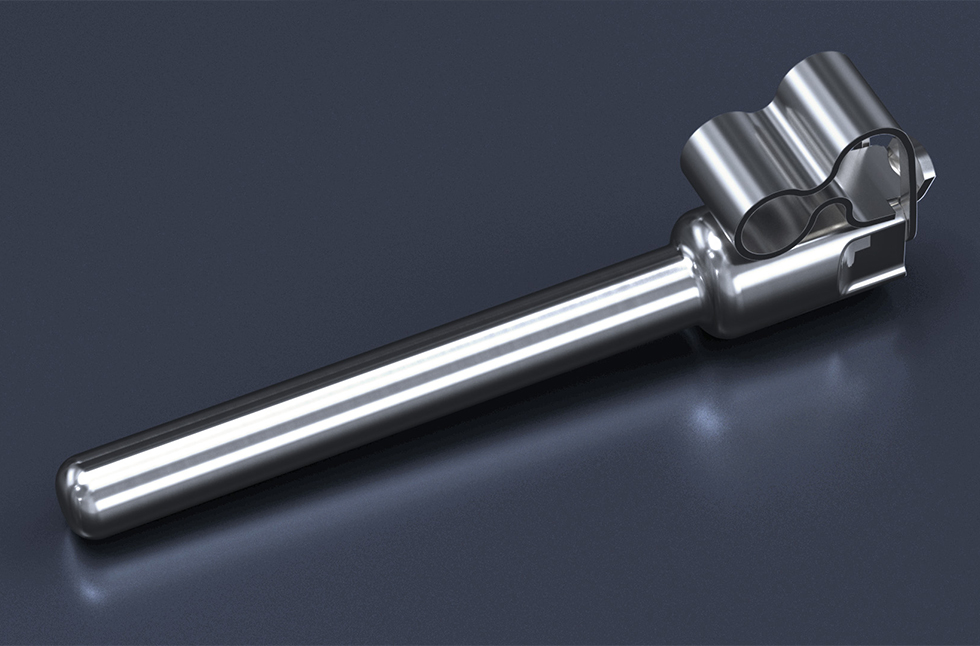

Efficient and resource-saving

1.5 million total plant investment plus product enhancements – and every cent pays off: For a customer in the electrical industry, we have taken the existing production of non-solid pins to the next level. Thanks to automated processes, modern machines and high-quality materials, costs have been reduced and product performance improved.

Our approach

We have completely rethought the original product, from the basic development to the manufacturing process and its practical implementation. Technological feasibility was taken into account from the outset, as were the functional requirements for the non-solid pins. Because these must meet the highest quality standards. Despite this already challenging task, we have also set ourselves the goal of minimizing the resources used.

Technologies used

In order to realize this ambitious project for our customer, we have defined our own concept with new technologies. This involved switching from a classic machining process to a new special production process with punching automation. We have developed, patented and technologically realized the new production specifically for this application.

Advantages for our customers

Thanks to a special manufacturing process, the amount of material required for the non-solid pins has been significantly reduced, which has also significantly lowered product and process costs. Despite less material-intensive production, the product performance was significantly improved and the technical properties of strength and conductivity remained the same. Most recently, it was possible to use a lead-free raw material.