Significant reduction in material requirements

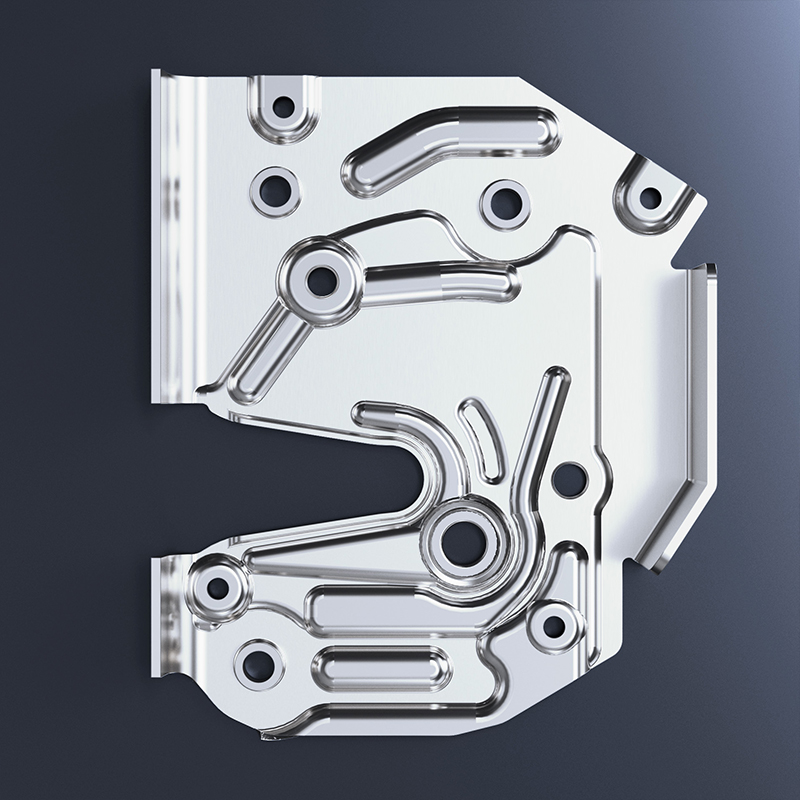

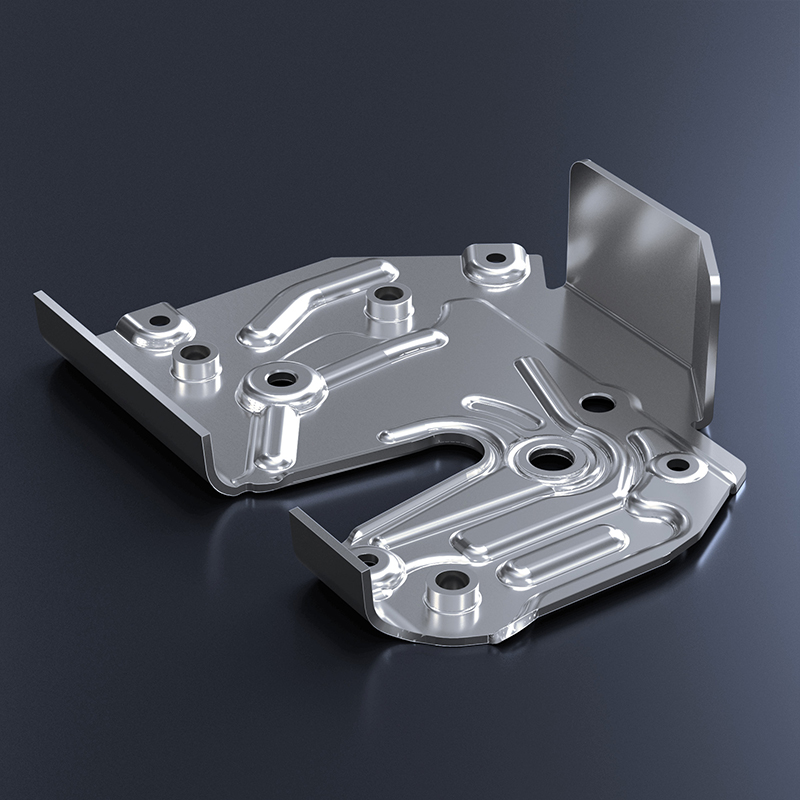

We were commissioned by a customer from the locking technology sector to develop and optimize a product design. In doing so, we should consider technological feasibility as well as functionality and potential material savings. The investment sum for the order was around 50,000 euros.

Our approach

The assignment presented us with a special challenge, as we had to implement various objectives. We therefore used an intensive planning and design phase to ensure the kinematic performance and requirements of the component and assembly. This was necessary as both have a safety-relevant function.

Technologies used

The product was created and simulated using CAD software and a CAE system. The subsequent application and method concept is planned for a follow-up composite system on a 630-ton servo press and was validated in advance using prototypes in laboratory tests.

Advantages for our customers

Thanks to our planning, the customer benefits significantly. We were able to reduce the use of raw materials by up to 20 percent – and that for an assembly that is used millions of times a year.