Efficient tool and equipment construction

Decisive competitive advantagesThe transformation of toolmaking 2.0 means engineering from Germany paired with global production. With this focus on “engineering local” and “production global”, we offer our customers a unique service. IBK offers its customers innovation and flexibility in toolmaking, significant price advantages, more capacity and a low risk of failure with short delivery times.

With us, you secure your market position and order opportunities considerably.

More success through

international toolmaking

Utilizing supply chains and synergies

As your local full-service partner, we develop and plan innovative tools and equipment completely in-house. Project support and communication with our customers takes place locally and globally. We manufacture the tools and equipment efficiently and to German standards in our partner plants in China. We optimize your supply chains, minimize risks and create synergies so that your materials and components are always in the right place at the right time. In this way, we ensure the very highest quality standards for your tools – and at a price volume that is up to a third lower than under purely national production conditions.

Our on-site service staff then check and hand over the tools and operating equipment to your production facility and offer you on-site service.

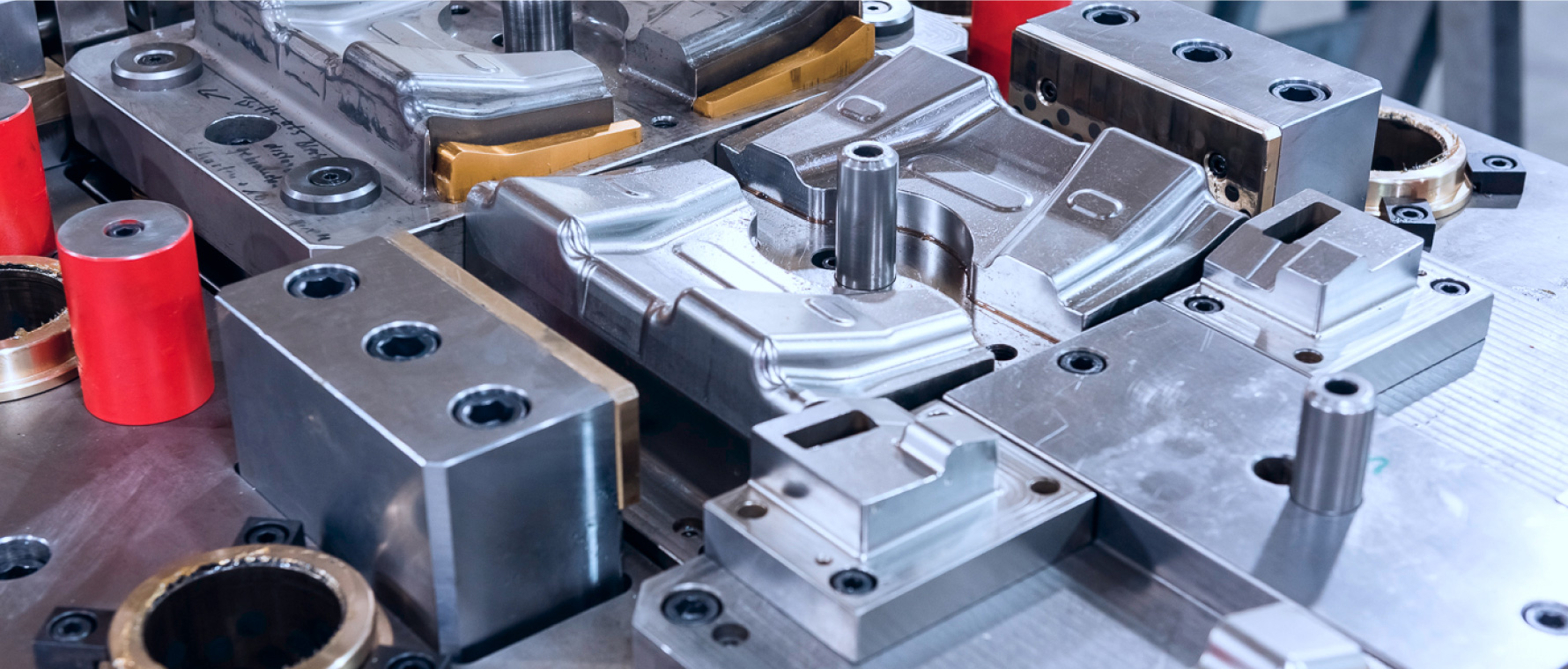

Our vertical range of manufacture

Our partnership results in valuable benefits for us and our customers:

We have more than:

- 500 experts

- over 100 modern CNC machines

- Presses with up to 630 tons of pressing force are available.

We are thus taking our vertical integration and high level of expertise in forming technology with a special focus on deep drawing and IAFT-based project management to a whole new level – even in the area of spare parts!

Procurement of operating resources for the following areas of tool design:

Stamped and formed parts

Assembly parts / assemblies

Devices

Special machinery and plant engineering

Tool and equipment construction for the following areas:

Customized tools

Punching, forming and deep-drawing tools, precisely tailored to your needs.

Many years of expertise

Decades of experience and a strong global network ensure the highest quality.

Cost-efficient solutions

Save up to 25% of costs through our international procurement strategy and optimized supply chains.

German standards

Quality control and project management according to German standards, both at home and abroad.

All-round service

From consulting and development to series production and maintenance – we accompany you through the entire process.

Global production advantages

Access over 500 experts and state-of-the-art machines in Asia thanks to our partnership.

Our supply chain process

Step 1

Advice on products, operating resources and processes

Step 2

Development of customized solutions

Step 3

International equipment and tool manufacturing

Step 4

Testing and series production readiness Training of the tool

Step 5

Delivery and support with initial setup

Step 6

Service for maintenance and repairs

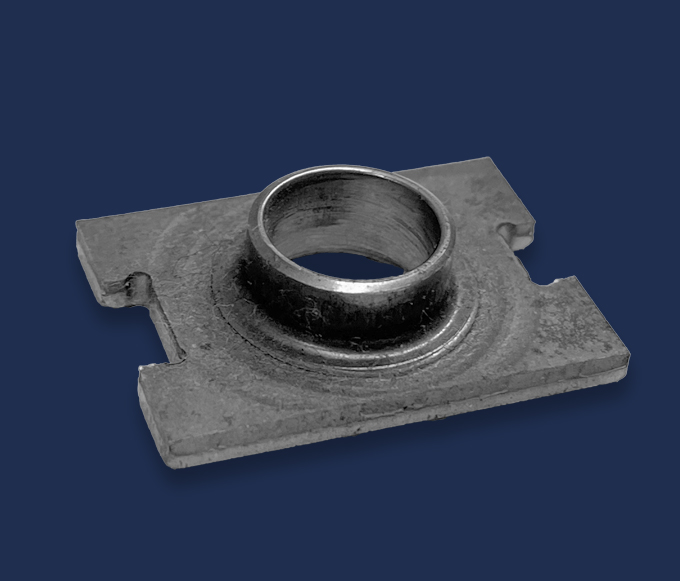

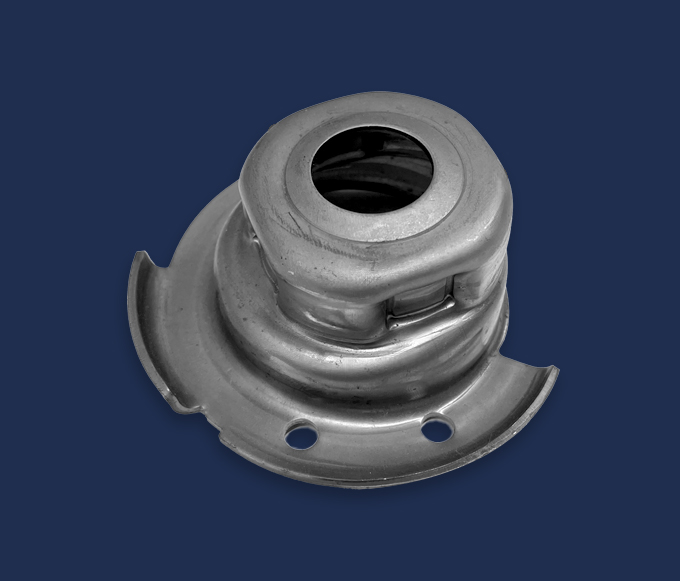

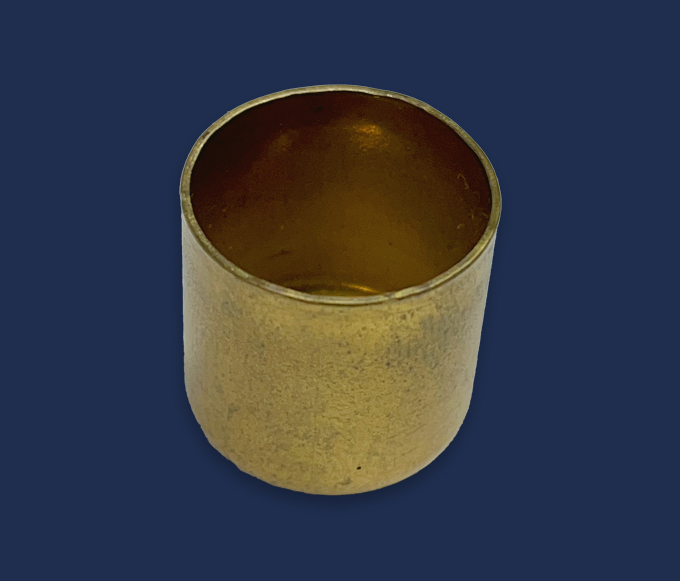

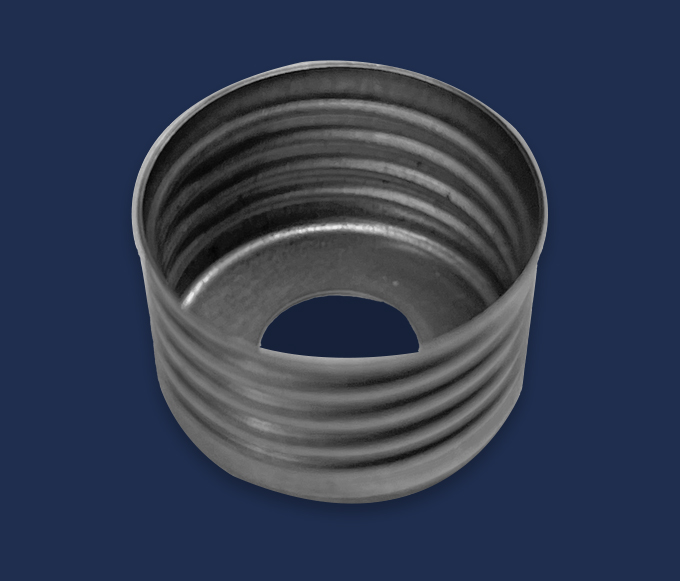

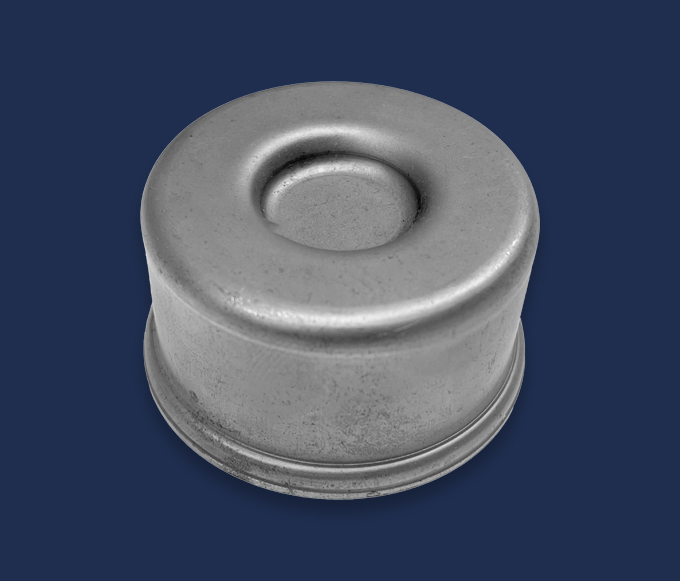

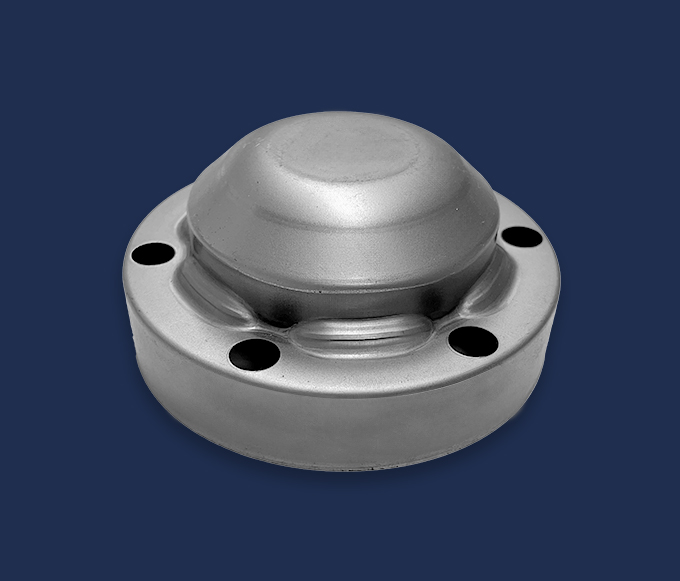

Deep-drawn parts

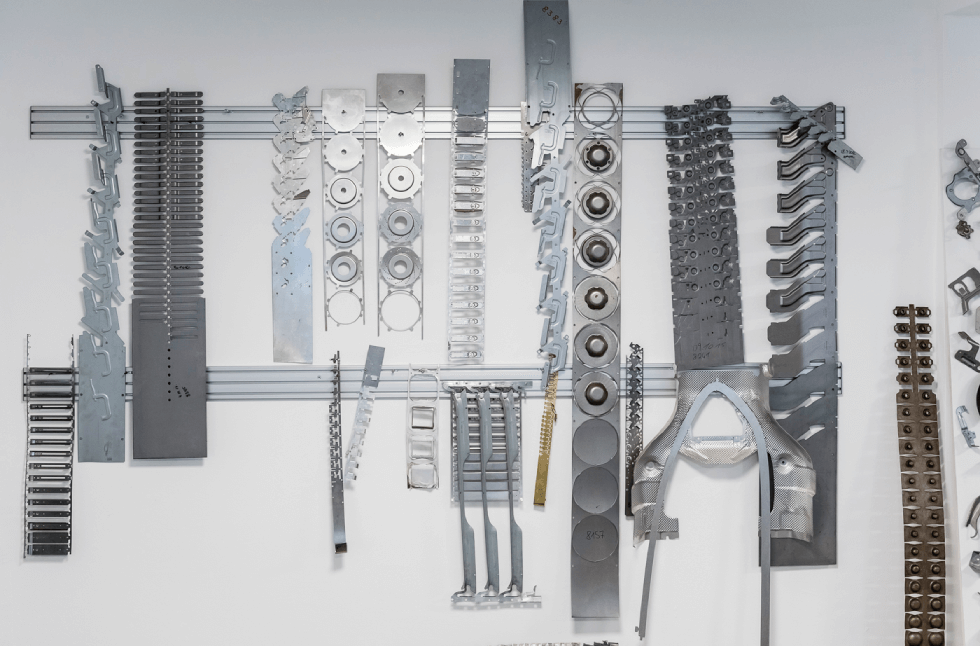

Examples of our daily work at

Engineering “Made in Germany”

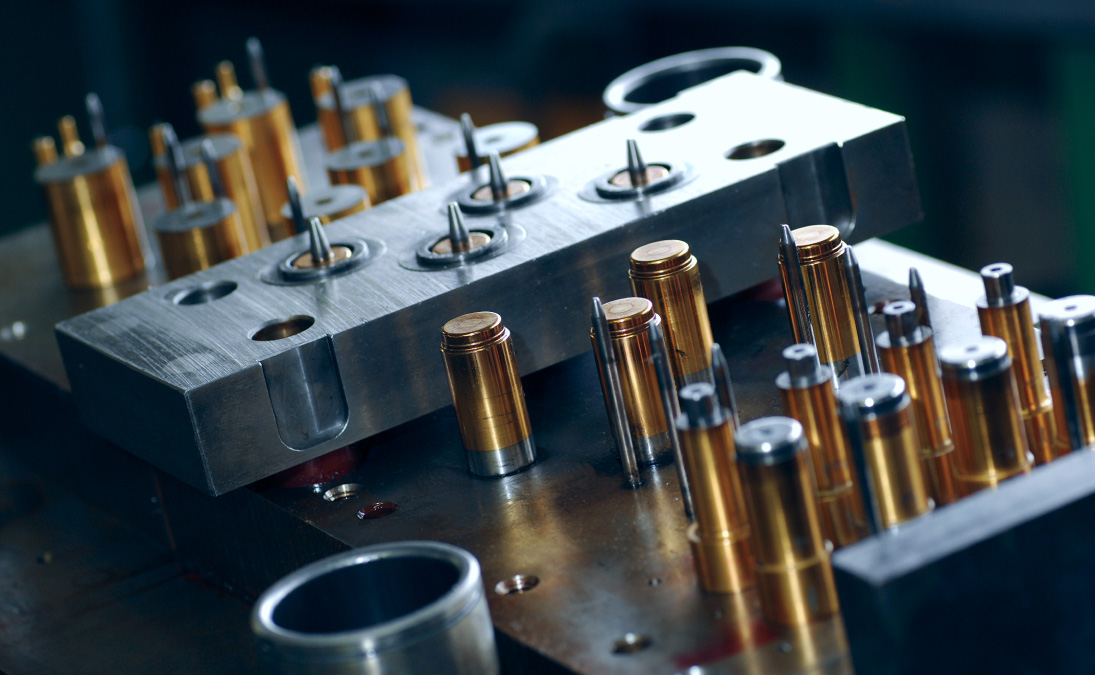

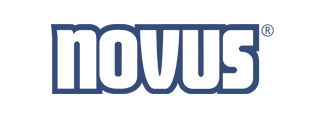

Progressive die incl. Thread forming

- Concept: 1 + 1 compartment

- Tool: 4,000 mm × 850 mm

- Pressing force: 850 t

Example images (tools)

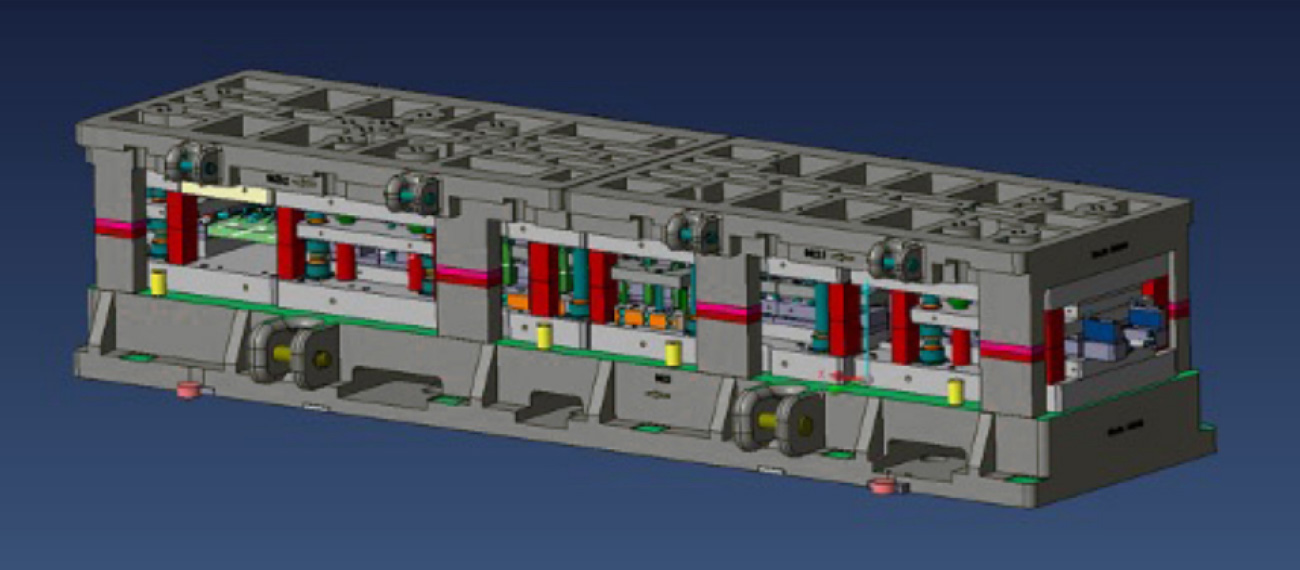

Full turnkey solution

Forming tools, presses and feed systems, 100% camera control and packaging systems

- Concept: 8-fold falling product

- Width: 2,000 mm × 1,500 mm

- Pressing force: 100 t

- Stroke rate: 100 strokes/min

Example image (special machines)

Further competencies in the overall process

For excellent performance along the entire process chain.

For maximum efficiency in all your company’s processes.

We look forward to your inquiry

Plans, goals, wishes, questions?

Hügelstraße 38–40 a (Office und Operation)

42279 Wuppertal

Deutschland

Current from industries and companies