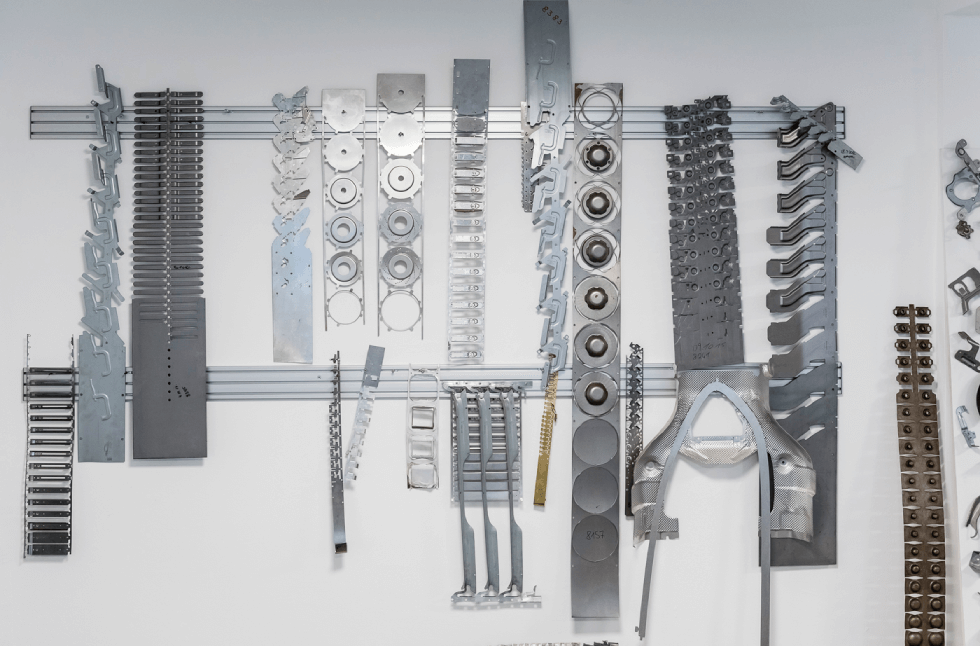

Quality up, costs down in tool design

Efficient and durable – these are the requirements that tool design in the field of stamping and forming technology should meet. This is the only way for companies to survive in a globalized market and under increasing price pressure. As an experienced manufacturer of punching tools and forming tools, we are on hand to advise you and act as a co-engineering partner. We explain the advantages of this in this blog post.

Up to 30% lower costs for the design of punching tools

How can material consumption be reduced in order to save costs? How can the specific requirements of a component be met? And how do you ensure precision and quality in series production? We come from the trade, our experts have all worked for decades in companies that specialize in punching and forming tools. That’s why we can advise you at both engineering and commercial level. We show ways and strategies to meet requirements with low material consumption. We optimize your process chain to reduce personnel and process costs with greater efficiency. We will explain to you how you can guarantee the precision of your products in the long term with a tailor-made quality management system.

The bottom line is that you save up to 30 percent on production costs compared to other European suppliers.

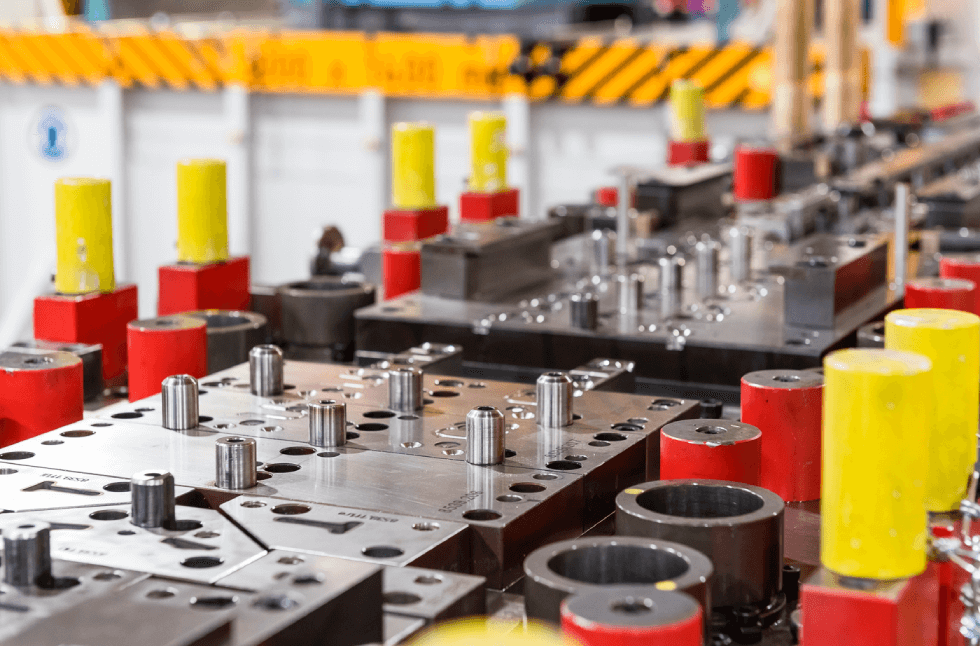

Individual solutions with co-engineering from IBK

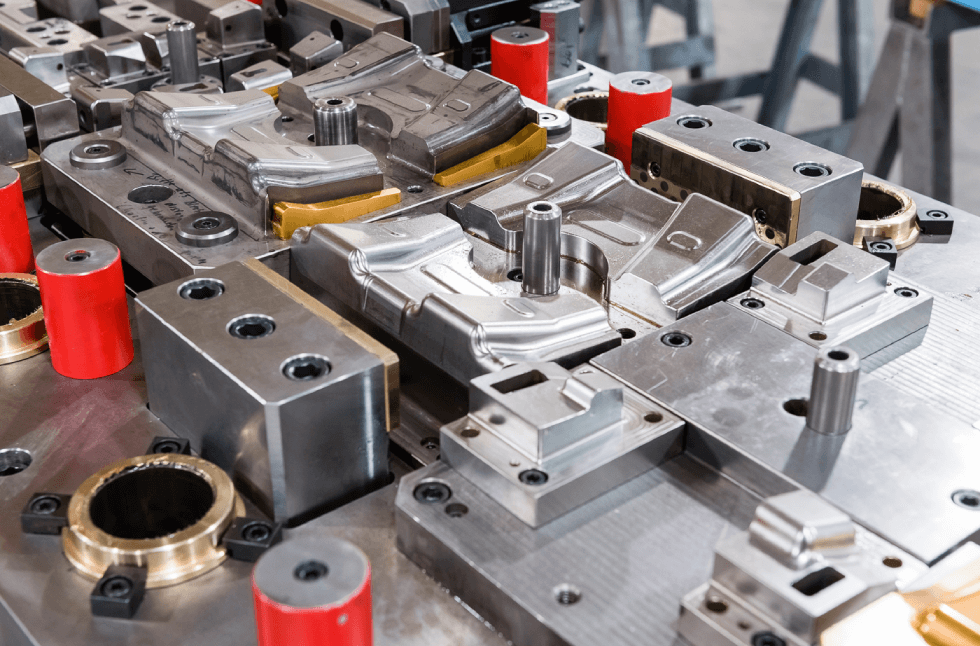

Of course, you can also contact us with your component requirements. Thanks to our experience, we know our way around all sectors and are therefore able to meet the respective specifications without any compromises. Our experts use the latest CAD and simulation software to design the ideal forming tool or punching tool for you. We use established processes to provide them with the best possible support.

Benefit from the ideal supply chain process for stamping and forming technology

- We contact our international partners and manufacturers to determine prices and delivery times.

- After carefully weighing up the price and delivery time, we award the contract and monitor the commercial and technical implementation.

- On completion of the project, we receive your stamping or forming tool and carry out a thorough inspection.

- Finally, we supply you with the tool and support you with the initial setup if required.

- Our service center in Wuppertal is at your disposal for subsequent maintenance or repair work.

Get unbeatable quality at a top price

We use international price pressure to the advantage of our customers and have access to a global supplier network. This allows us to offer you high price flexibility and guaranteed delivery times. Nevertheless, we offer you genuine “Made in Germany” quality engineering. This also includes German project management and corresponding process monitoring. Quality control and subsequent maintenance work are also all carried out in Germany.

Would you also like to benefit from all the advantages of our services in the procurement and design of stamping and forming tools? Then start your inquiry now and get in touch. Our experts look forward to hearing from you!