Through efficient and market-compliant products

SUCCESS IN METAL FORMING

Professional support for

Product development and product design

Metal forming technology is a complex process that places high demands on product design as well as on method planning, the processes used and material reduction. The aim is to improve product quality and functionality while at the same time optimizing processes and resources. Based on our decades of experience, we support you in all process steps.

We develop for you:

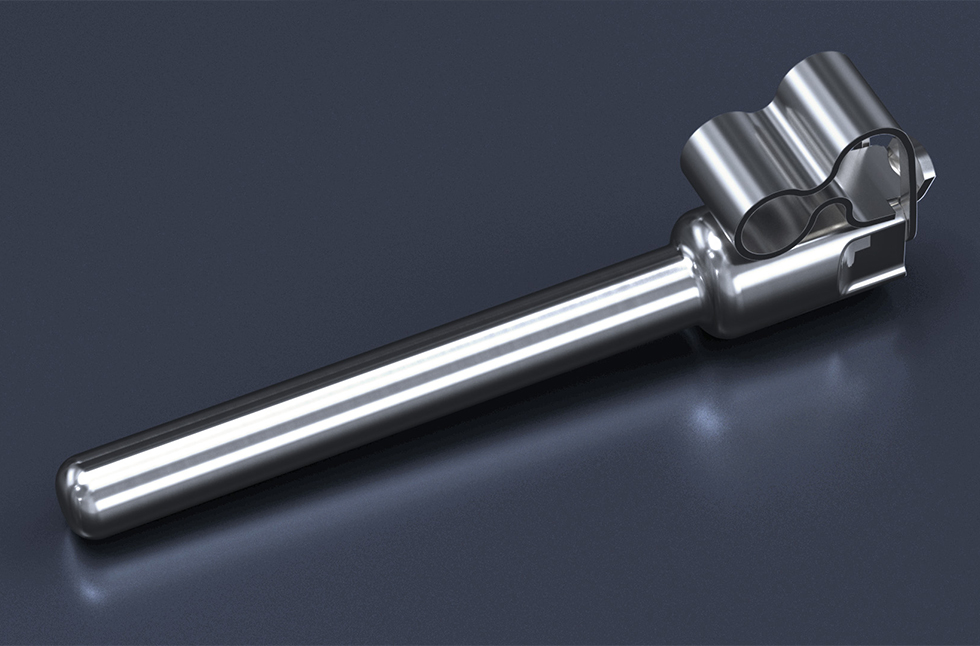

- Decorative elements

- Punched parts

- Pressed parts

- High-gloss parts

- Mounting parts & assemblies

Technical and commercial evaluation taking into account international competition

Is your product idea ready for the market? Our experts constantly monitor the market and trends in metalworking and metal forming. We are therefore able to identify opportunities and risks at an early stage and can support you in adapting your business strategy accordingly. With our analyses on the topics of “product market fit” and “product solution fit”, we create an important basis for further product development. Of course, we can also provide you with professional support in calculating your project. Ultimately, your business success also depends on you calculating the costs of manufacturing an end product accurately enough in advance to ensure the profitability of the project.

Successful product and process development

The requirements for the geometry and functionality of the end product are determined as part of the product design. In this process, we not only consider the selection of the appropriate material, but also focus on the manufacturability in the industry and resource-saving implementation. We support you in reducing costs in the development of products and processes. By applying design-to-cost methods, we can help you optimize your cost structure and increase your competitiveness.

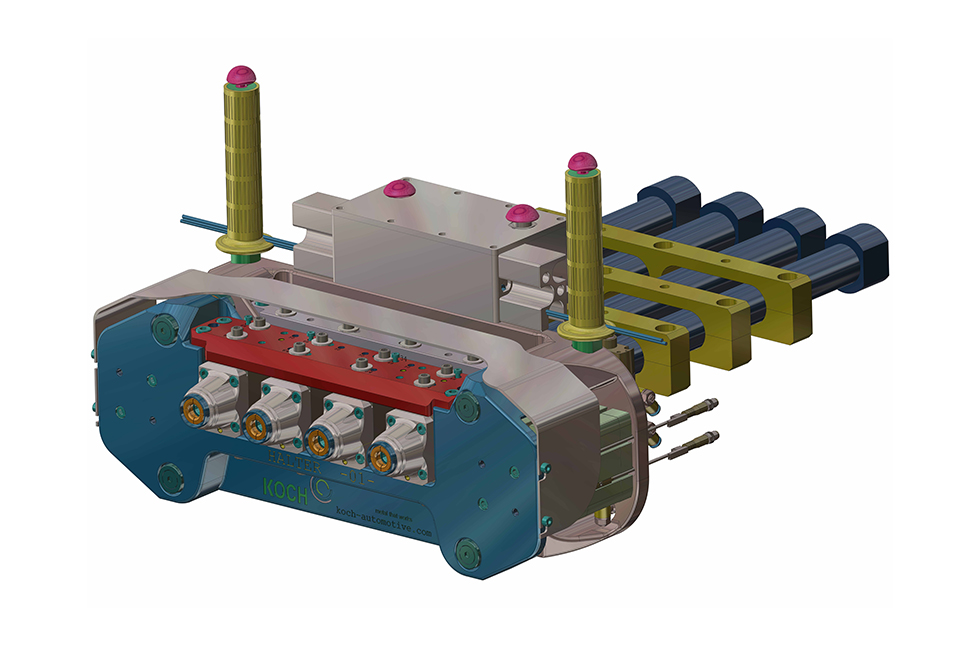

Optimum tool design

Whether you want to produce small or large series – we support you in every case. Because we know that these are different requirements for tool design and process optimization. In small series, it is more important to change and adapt the design more quickly, while in large series, process stability and repeatability are important – and we are the experts in both areas and will design the optimum tool for you.

Error minimization through CAE simulations

With the help of simulation processes, in which we simulate the forming processes in advance using CAE systems (Computer Aided Engineering), we are able to optimize all process parameters. By eliminating potential sources of error before production, we increase the efficiency of the processes and ensure component manufacturability.

Increase efficiency through method planning, manufacturability and feasibility analyses

Method planning involves the selection of suitable forming processes, the definition of forming processes and the optimization of process parameters. Material reduction is another important aspect of metal forming technology. The advantages are obvious: production costs are reduced and the environmental impact is minimized. We achieve this by optimizing forming processes, using high-strength materials and recycling materials, among other things.

Examples of our product developments

Engineering “Made in Germany”Over the years, we have driven forward and implemented many interesting product developments. Whether decorative components, structural components, locking technology or deep-drawn parts – we provide our customers with professional support from product design, product development and product management through to production technology.

We look forward to your inquiry

Plans, goals, wishes, questions?

Hügelstraße 38–40 a (Office und Operation)

42279 Wuppertal

Deutschland