TOOLMAKING AND PROCUREMENT OF OPERATING RESOURCES

Co-Engineering Partner

You too can benefit from our engineering expertise and global procurement management

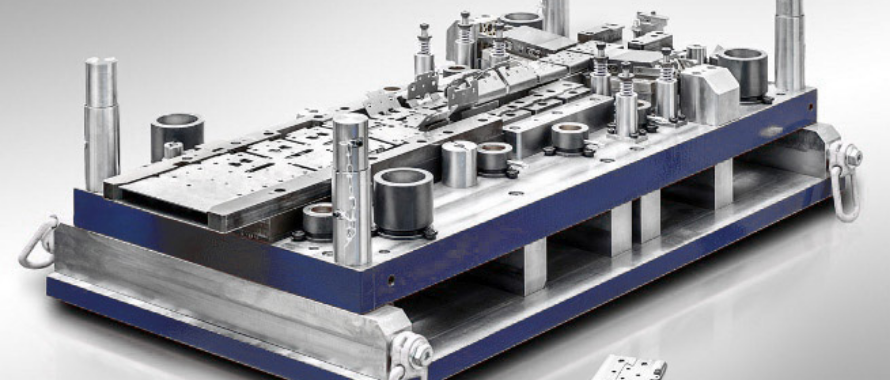

Toolmaking and design

We supply the optimum tool for your forming process.

Do you need the right tool? Based on our decades of experience and a large pool of international suppliers and toolmakers, we supply you with innovative and precise tools for effective and efficient forming processes.

We deliver to you:

- Punching and forming tools

- Thermoforming tools

- Spare parts

- Devices and special machines

- Automated system solutions

Global procurement management for operating resources

Our comprehensive expertise in global procurement management enables us, as your full-service partner on site, to develop innovative operating resources completely in-house and manufacture them with our partners. We understand the dynamics of the sheet metal processing market and not only maintain our core competencies and service at the highest level, but also work together with high-performance partners to offer you cost-effective solutions. With our experience and flexible approach, we not only offer quality, but also the best prices on the global market. We optimize your supply chains, minimize risks and create synergies so that your materials and components are always in the right place at the right time.

And with our partnership with Premier Toolingan expert for the Chinese market with excellent contacts to suppliers and partners there, we now have more than 500 experts, over 100 modern machines and six established suppliers from the Asian region at your disposal. This takes our vertical integration and capacities to a whole new level for you.

This means: quality up, price down!

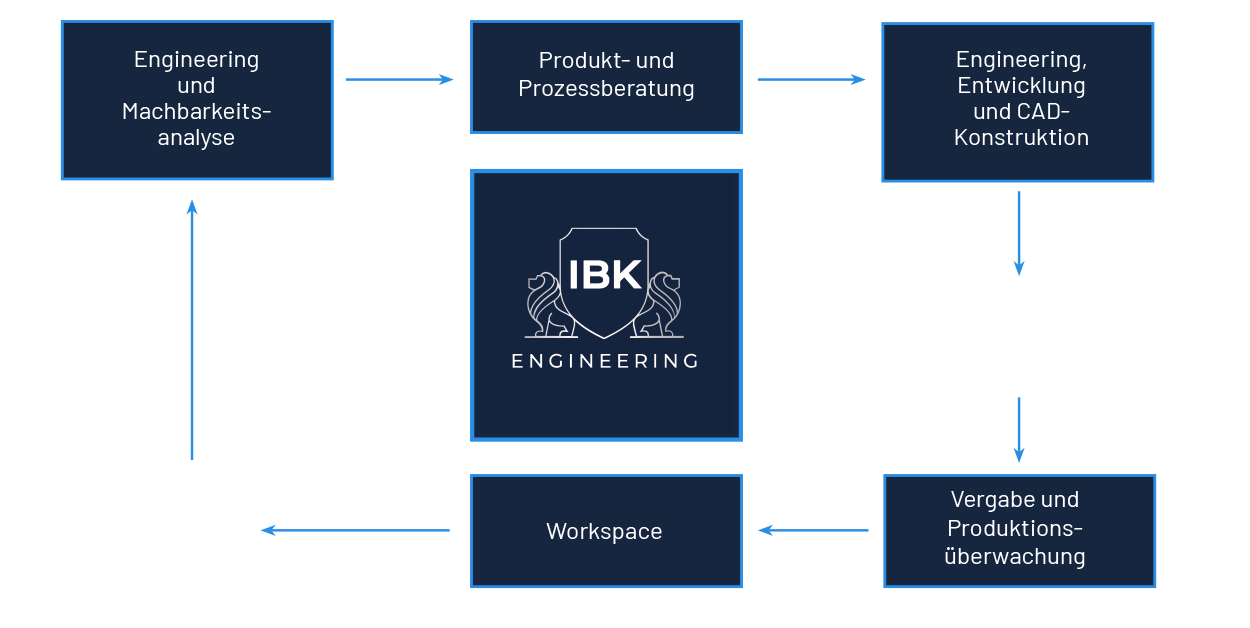

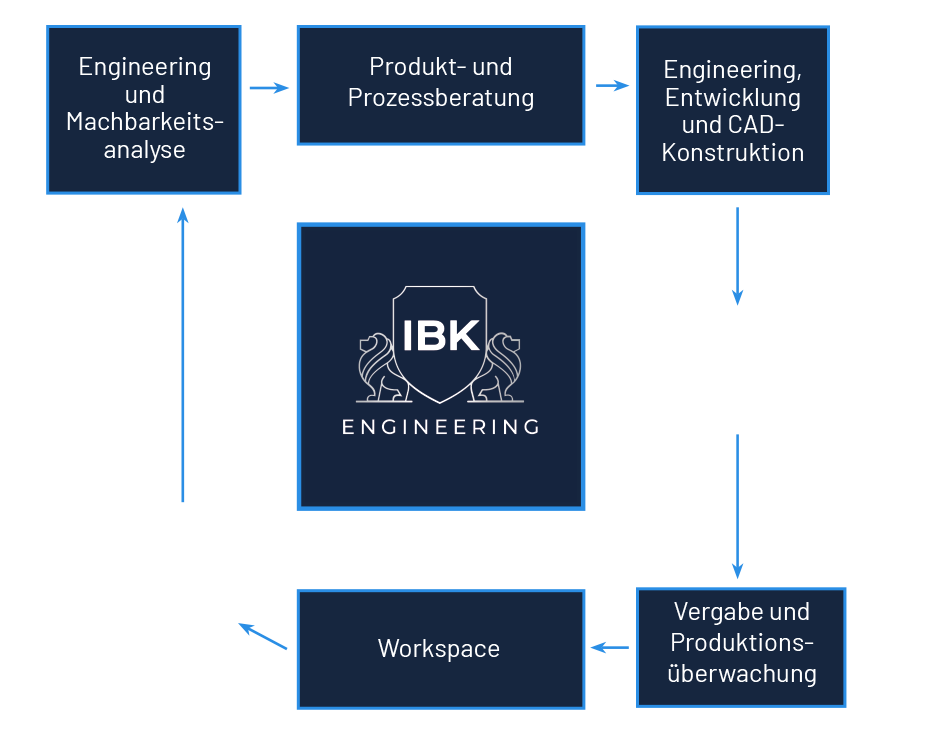

Our supply chain process:

- We advise you on products, equipment and processes

- We develop and design customized solutions together with you

- We enquire with our international manufacturers, taking into account price and delivery dates

- We award the contract and manage the commercial and technical implementation

- We receive your tool after completion and subject it to precise testing, coordination and readiness for series production

- We supply you with the tools and support you with the initial setup

- We are at your side for subsequent maintenance or repair work at our service center in Wuppertal

Your advantages:

- Large international selection of suppliers

- Greater flexibility in terms of price and delivery times

- Up to 25 % cost savings (compared to Germany)

- Engineering “Made in Germany”

- Project management and process monitoring in Germany

- Quality control according to German standards

- Subsequent maintenance and repair work in Germany

Examples from our daily work

References

Progressive die incl. Thread forming

- Concept: 1 + 1 compartment

- Tool: 4,000 mm × 850 mm

- Pressing force: 850 t

Example images (tools)

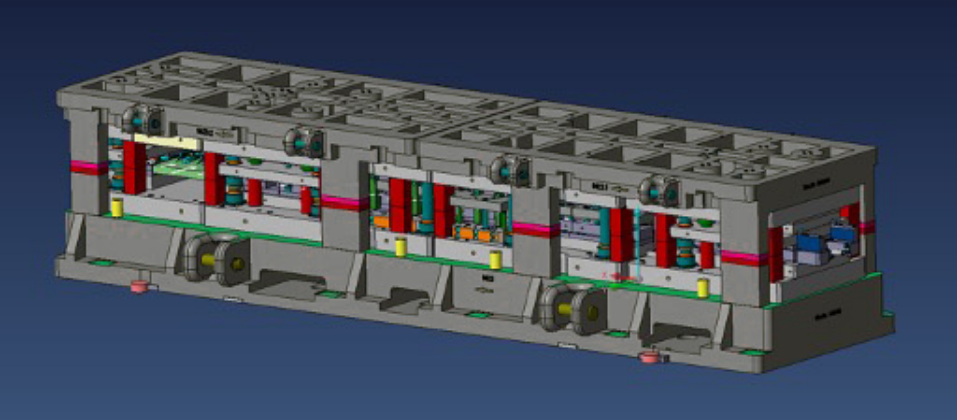

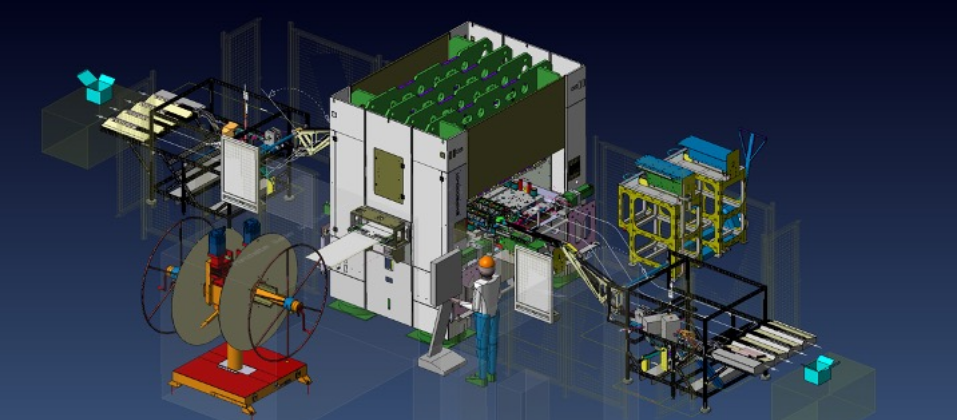

Full turnkey solution

Forming tools, presses and feed systems, 100% camera control and packaging systems

- Concept: 8-fold falling product

- Width: 2,000 mm × 1,500 mm

- Pressing force: 100 t

- Stroke rate: 100 strokes/min

Example image (special machines)

We look forward to your inquiry

Plans, goals, wishes, questions?

Hügelstraße 38–40 a (Office und Operation)

42279 Wuppertal

Deutschland